Description of the Argos

Innovative inspection system for incoming and outgoing goods.

More and more companies observe manual inspection and control of in/out goods flows as a bottleneck. Any error that occurs in this process results at a later stage in multiple problems. Amongst others, these consist of additional labor, process disruption, dissatisfied customers, and the burden of proof to suppliers.

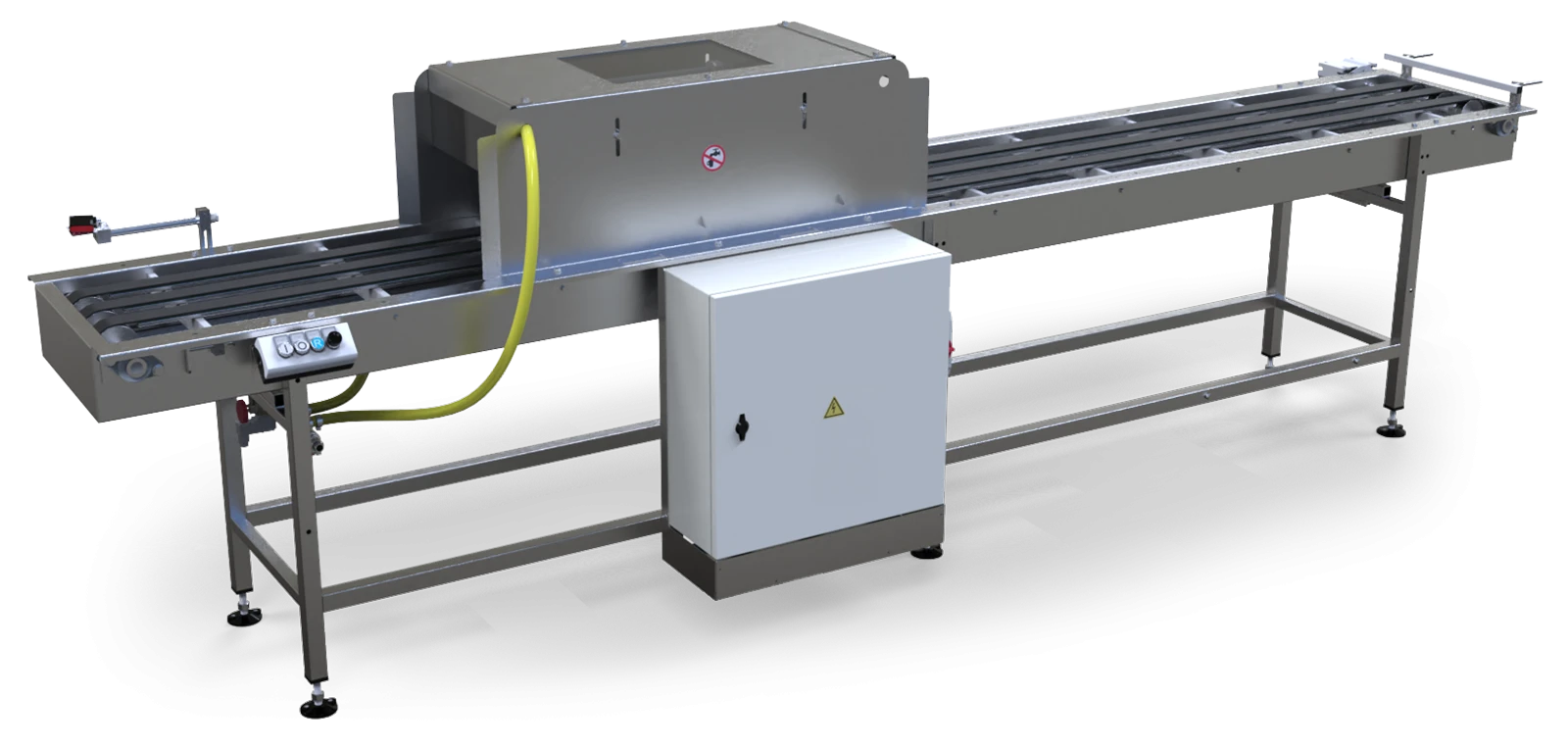

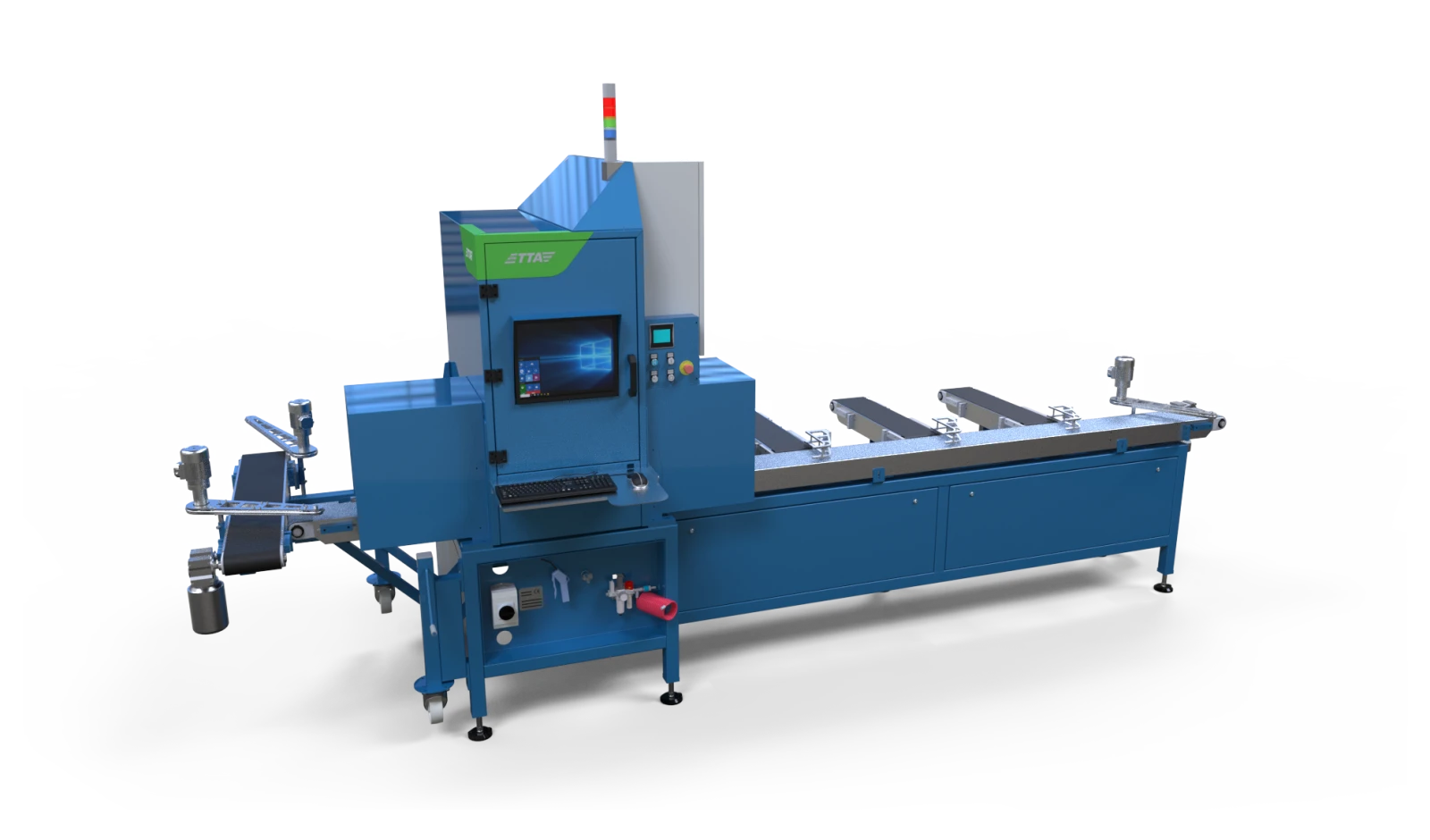

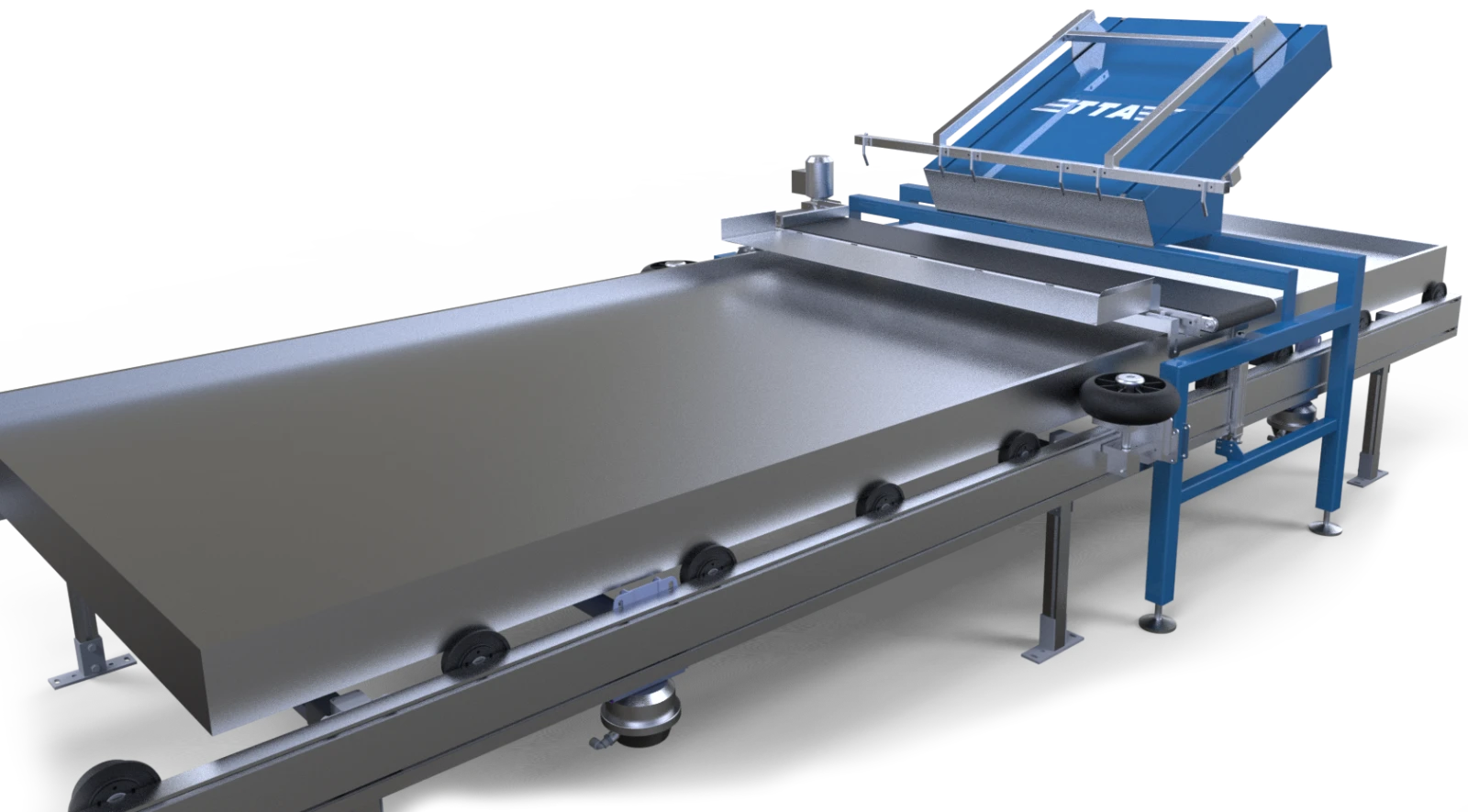

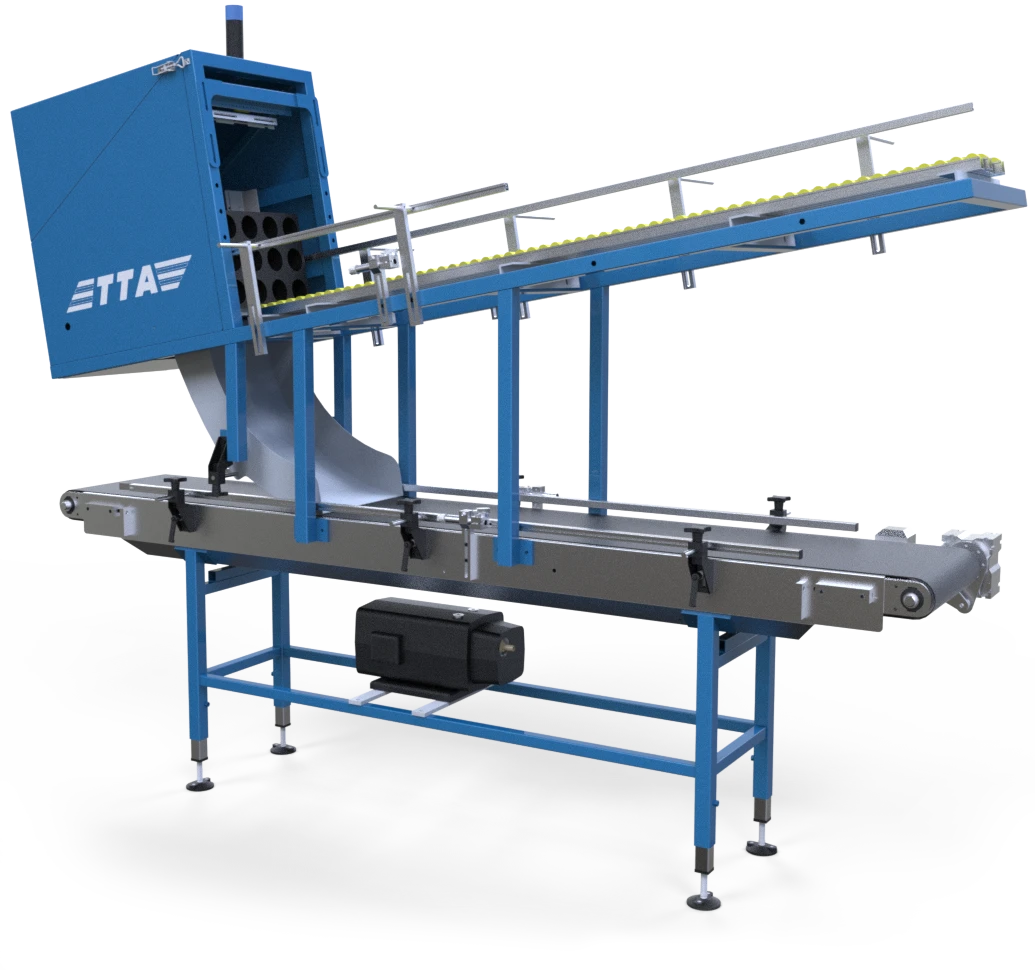

In cooperation with a large launching customer, the Argos was developed. The Argos provides an intelligent inspection system that processes all available and measurable data of a load carrier by intelligent multi-Vision scanning. It executes this fully automatically as well as ‘on-the-flight’.

A load carrier (Danish trolley) is fed into the infeed system of the Argos. The Argos transports the load carrier independently through the inspection tunnel. All products on the load carrier are scanned using intelligent multi-Vision technology. In the process, a multitude of data was measured, such as:

Optical image of the entire load carrier

Product code

The precise location of each product on the load carrier

Product height per cask

Control of the total number

RFID tag registration

Benefits

Automated inventory management

Automatic triggering of EAB/invoices to customers

Value chain status update that the product has been shipped

Chain savings

Exit control grower & exporter input control

Quality inspection of outgoing products by intelligent 4th-generation vision optical technology

Argos

in action

Argos - Royal Lemkes

Argos

Get in touch

with us

Interested in TTA’s Argos?

We are happy to advise you!

→ +31 (0)184 69 11 05

→ sales@tta.eu

.webp)