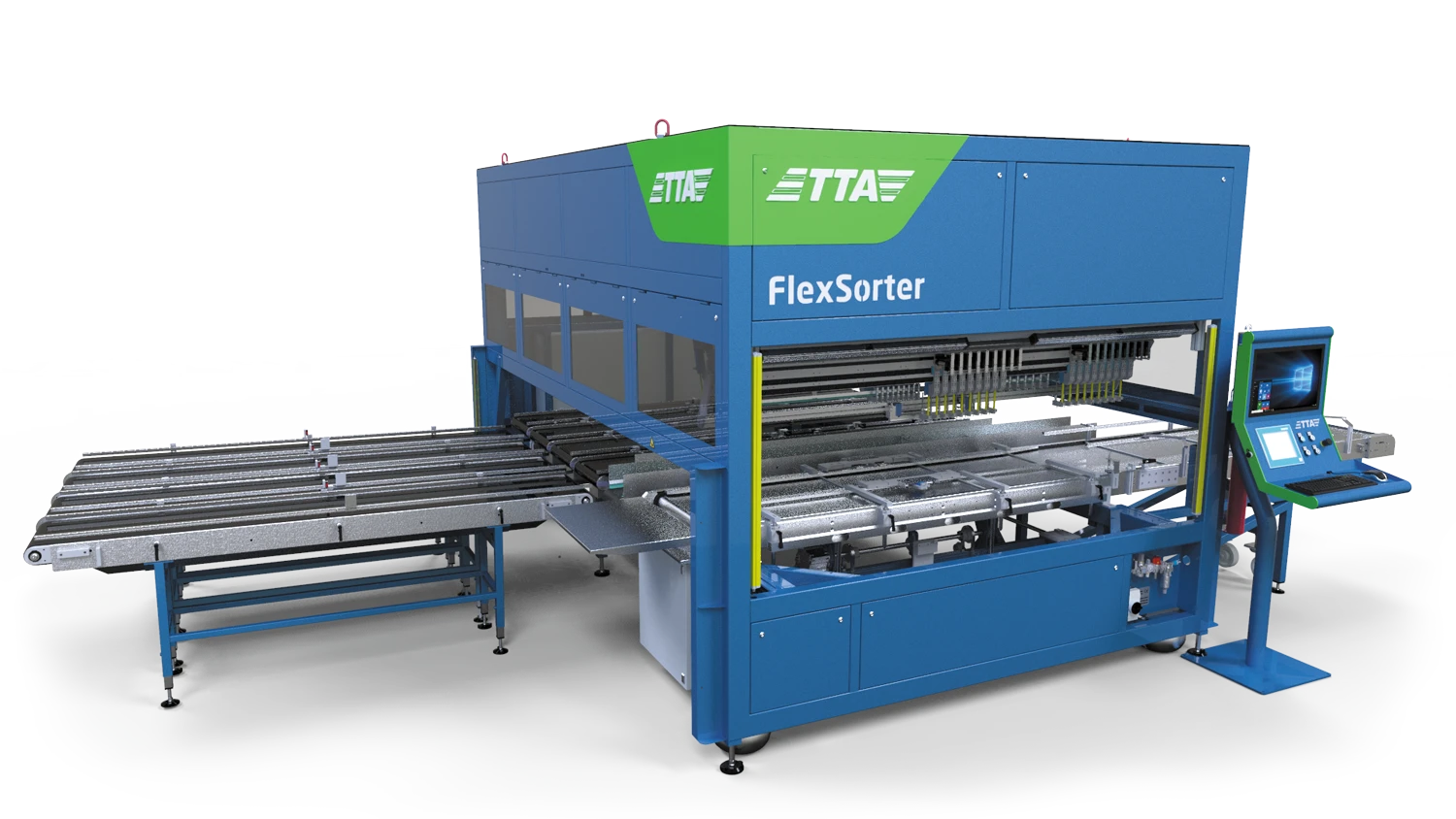

Description of the FlexSorter XF

Ultra high-speed grading line.

The FlexSorter XF is an ultra-high-speed automatic selecting line that can sort and transplant young plants into different grades. The FlexSorter XF is provided with our VisionPlus camera selection system, which features three cameras and can be extended with more cameras for selection based on multiple angles or to select based on different technologies (RGB and/or IR).

The FlexSorter XF conveys the donor trays into the machine using a chain belt, which buffers the trays. When the tray is in the correct position, the pick and place unit moves to the first row and picks up plugs from the donor tray with our in-house developed plant grippers. At the same time, our pusher pin system comes up from underneath and pushes the plants—a very useful method, especially for plant material with under or overdeveloped roots.

The pick and place unit moves to the selection position upon pick up. Our imaging system qualifies every plant using camera units at this position. After qualification, the plants are transplanted into trays/packs and positioned on the destination conveyor belt. Waste plugs are dropped on a small conveyor belt when the pick and place unit returns for the following row of plants.

Each plant gripper is driven by its own direct linear drive motor unit, controlled by an individual microprocessor. This unique TTA development enables you to teach new trays and plant patterns easily. The plant grippers can pick up the plants with an adjustable shift movement to reduce plant damage. The number of plant grippers depends on the required capacity and tray size.

Specs

Operators

1

Capacty per hour

10.000 - 30.000 plugs

FlexSorter XF

in action

Get in touch

with us

Interested in TTA’s FlexSorter XF?

We are happy to advise you!

→ +31 (0)184 69 11 05

→ sales@tta.eu