Description of the Mobile Blow Out

The MBO identifies and extracts missing plants from trays to prepare them for manual fixing.

The MBO identifies and extracts the missing plants in order to prepare the trays for manual fixing. The production speed is up to 600 trays per hour.

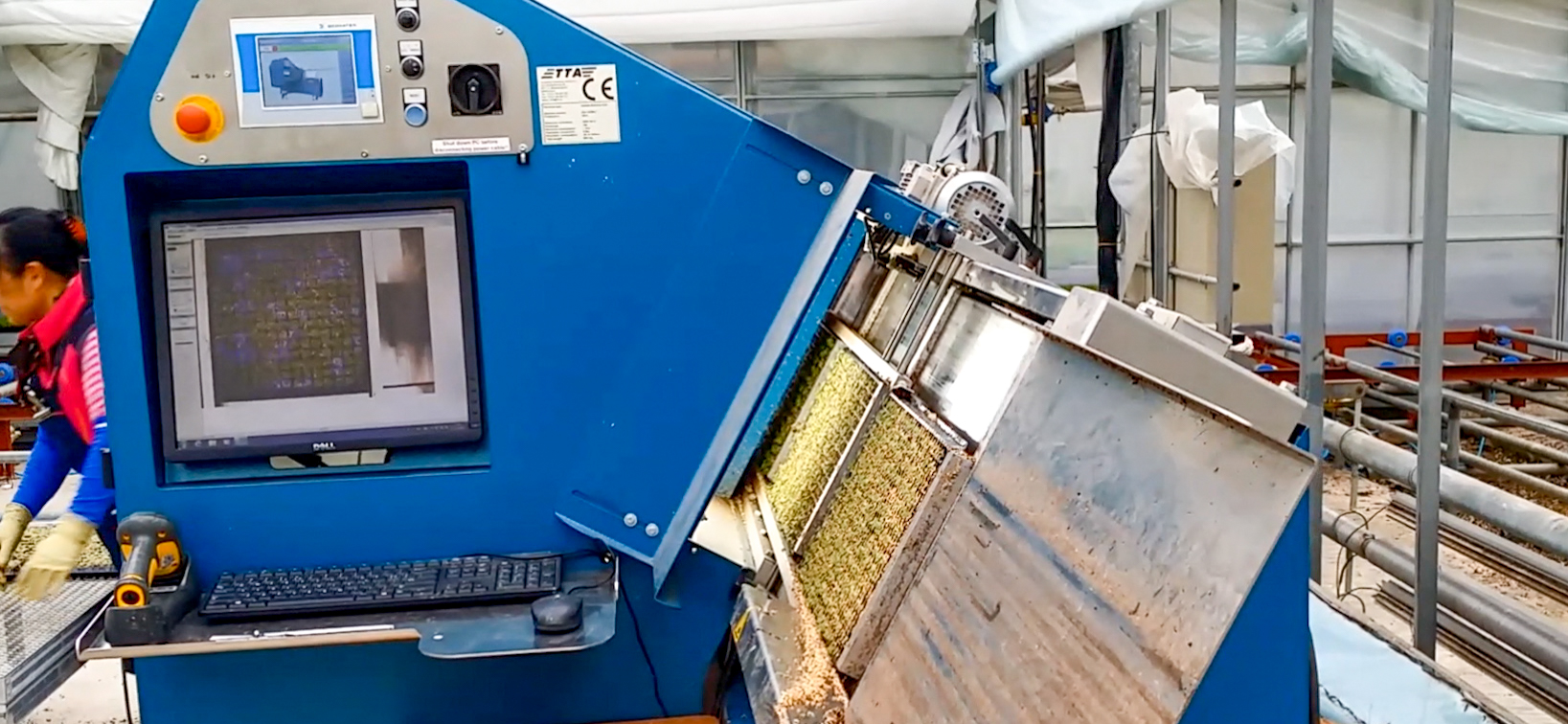

Trays with young plants will manually be placed into the MBO. They will be identified with TTA's in-house developed imaging system. The selection on the plant material can individually be adapted. For instance values like plant size, plant color, position of the plant on the plug etc. can be altered depending on the plants or current growing circumstances.

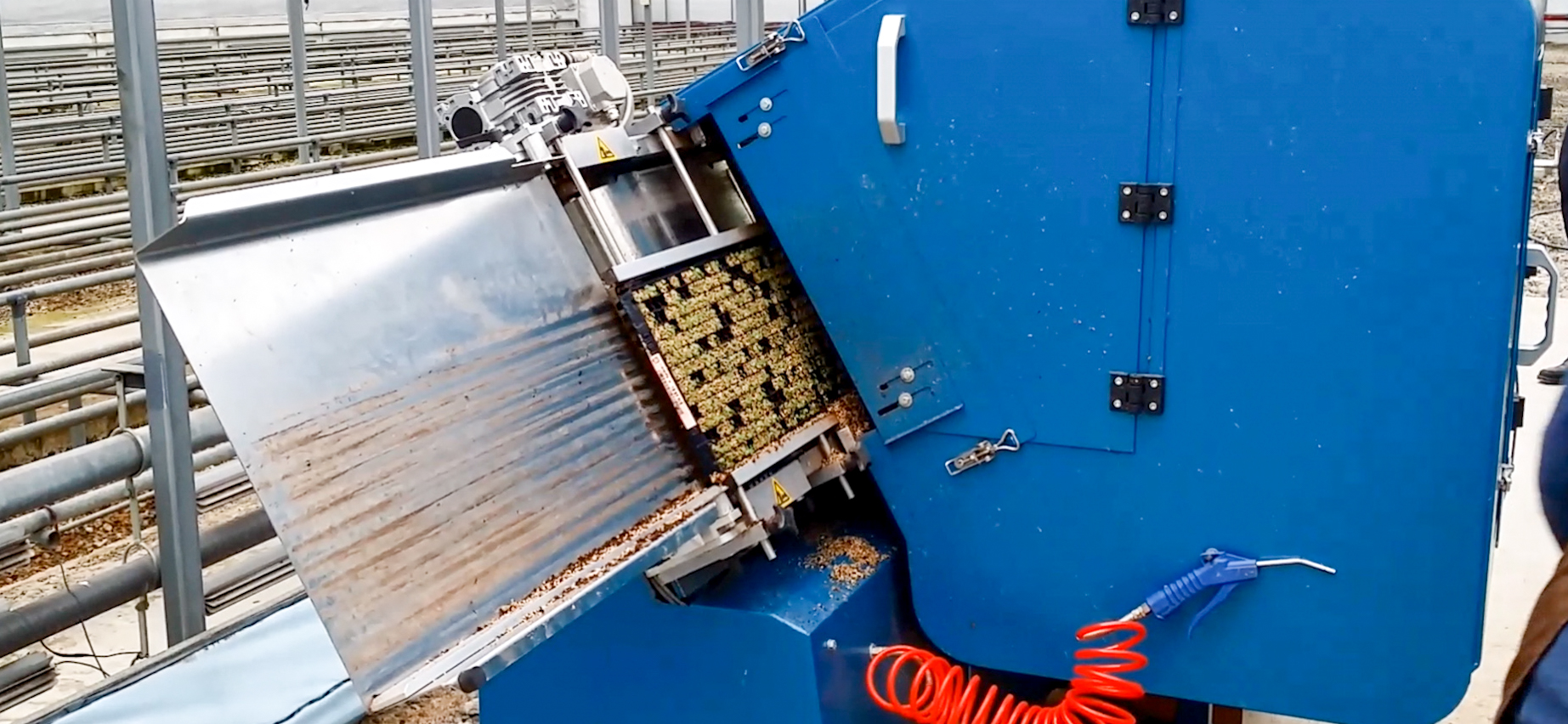

Depending on the settings, single plugs will be removed out of the tray. TTA's imaging system runs under Windows and is very user-friendly. After the selection part, the trays come into the blow-out part, where the NOK plugs will be removed out of the tray. The removement take place with air nozzles which blow the plugs out of the tray from below.

The blow-out section can easily and quickly be adapted to another tray size by means of an interchangeable blow-out bar. In the MBO, one complete tray setup is included. The removed plugs will be dispatched sideways towards two boxes. With respect to tray sizes, all usual tray sizes can be handled (maximum tray size 600x400 mm). The complete tray change-over time is under 15 minutes. All plug tray settings can be stored in the memory.

Specs

Operators

1

Capacity ph

600 trays

Plug diameter

9-20 mm

Mobile Blow Out

in action

Mobile Blow Out - Korea-America

Mobile Blow Out

Get in touch

with us

Interested in TTA’s Mobile Blow Out?

We are happy to advise you!

→ +31 (0)184 69 11 05

→ sales@tta.eu