Indoor farming and CEA facilities

High-tech

automation

solutions

Indoor farming isn’t just about meeting today’s needs; it’s about securing tomorrow’s resources. To feed the future, the way of growing crops needs to aim higher. That’s why TTA develops high-tech automation equipment for indoor farming and CEA facilities – to help feed the growing population more sustainably.

The future of

sustainable food

At TTA, we believe that CEA holds the key to the future of sustainable food production. By growing crops within fully controlled environments, farmers can overcome traditional agriculture’s challenges—such as climate unpredictability, water shortages, and limited arable land. Indoor farming solves these issues, enabling the cultivation of high-quality crops year-round, regardless of external conditions.

Combining

technologies to

create the future

of food

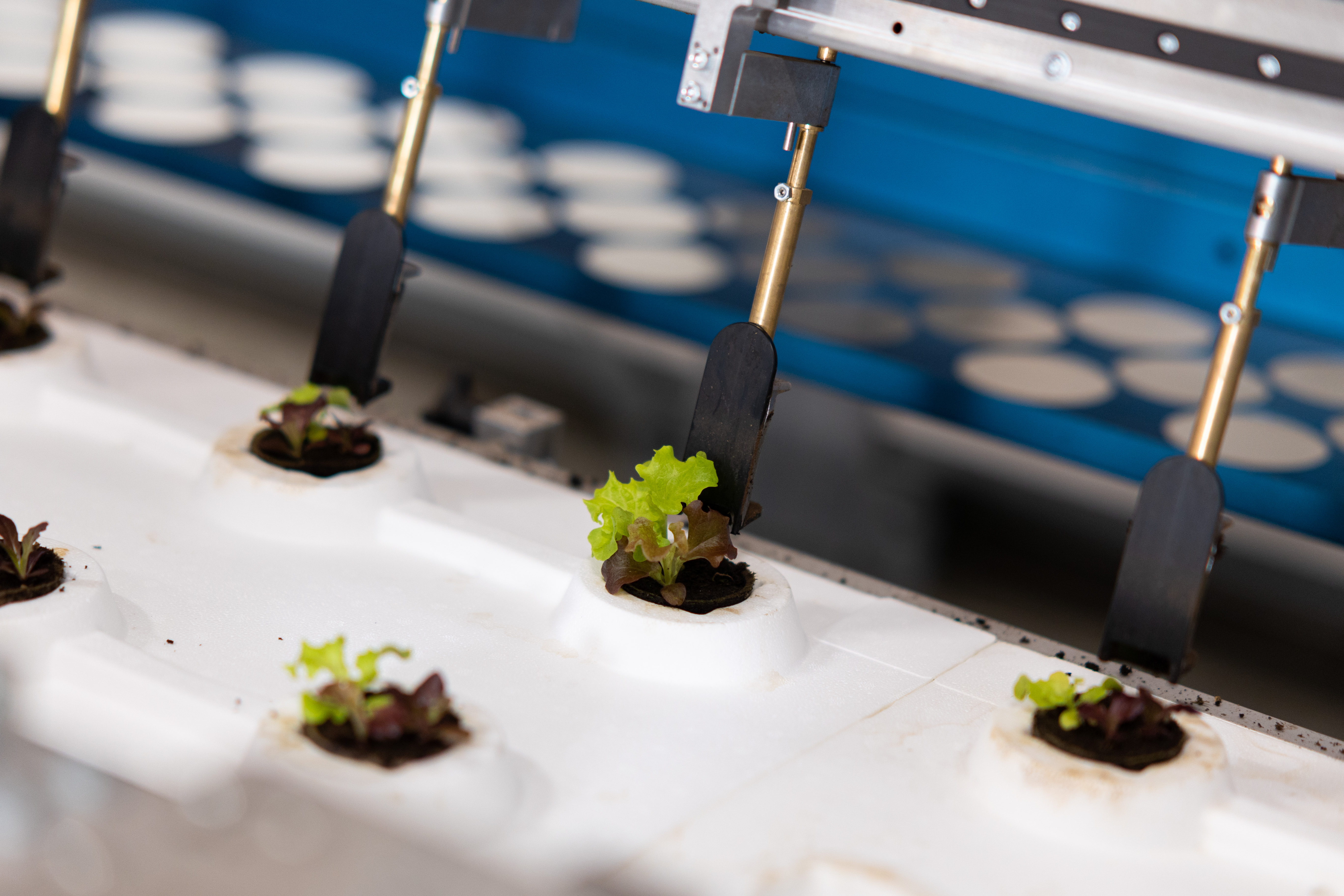

TTA’s vision for CEA focuses on driving automation and innovation to make indoor farming more efficient, productive, and sustainable. We provide indoor farms with the latest technologies for sowing, transplanting, selecting, and harvesting plants to guarantee healthy and uniform indoor-grown crops. Lowpad AMRs (Autonomous Mobile Robots) handle internal transportation. Automating indoor farming reduces production costs, improves plant quality, and increases yield.

Testimonial

I appreciate TTA’s emphasis on identifying the future needs of vertical farming, which is why I want to continue working with them. Instead of adapting vertical farming to open fields or greenhouse technology, which isn’t the right fit, TTA is focusing on developing automation solutions specifically for vertical farms. This is the reason we chose to work with TTA. The FlexPlanter has helped us improve our yields, reduce waste, and optimize our limited growing space with plants that wouldn’t have prospered otherwise.

Tisha Livingston

Co-Founder of 80 Acres Farms

How would you like

your vegetables to

grow?

We can seamlessly integrate with any growing system. Professional farms worldwide use different cultivation methods based on factors such as crop cycle and layout. TTA’s equipment is designed to be compatible with nearly all hydroponic systems, including Mobile Gutter Systems (MGS), Deep Water Culture (DWC), and Multilayer Systems, ensuring that our solutions fit any growing setup.

Mobile Gutter Systems (MGS)

A Mobile Gutter System (MGS) replaces soil with a nutrient-rich water solution. An in-line pump circulates the water through the plant’s roots, providing precise control over water and nutrient intake without over-soaking. This method is ideal for fast-growing plants like lettuce and herbs.

Deep Water Culture (DWC)

Deep Water Culture (DWC) keeps plant roots submerged in 15 to 20 centimeters of nutrient-rich, oxygenated water. Plants are placed on floating trays, with their roots hanging directly in the solution, which is aerated by an air pump and aeration stones. This continuous supply of oxygen-rich nutrients promotes rapid and vigorous growth.

Multilayer Systems

Multilayer Systems are commonly used in vertical farms, where vegetables are grown in controlled environments without external influences. This method optimizes plant growth by providing precise amounts of oxygen, water, nutrients, and LED lighting. It also conserves space, energy, and water, allowing for year-round production and higher yields.

Get in touch

with us

Curious about how our cutting-edge automation solutions make a difference? Don’t hesitate to contact us; we’re eager to advise you.

Call→ +31 (0)184 69 11 05

→ sales@tta.eu