Transplanting plugs

FlexPlanter

Transplanter that combines transplanting and selecting.

FlexPlanter XF

Ultra-high-speed transplanting line which transplant young plants into different grades.

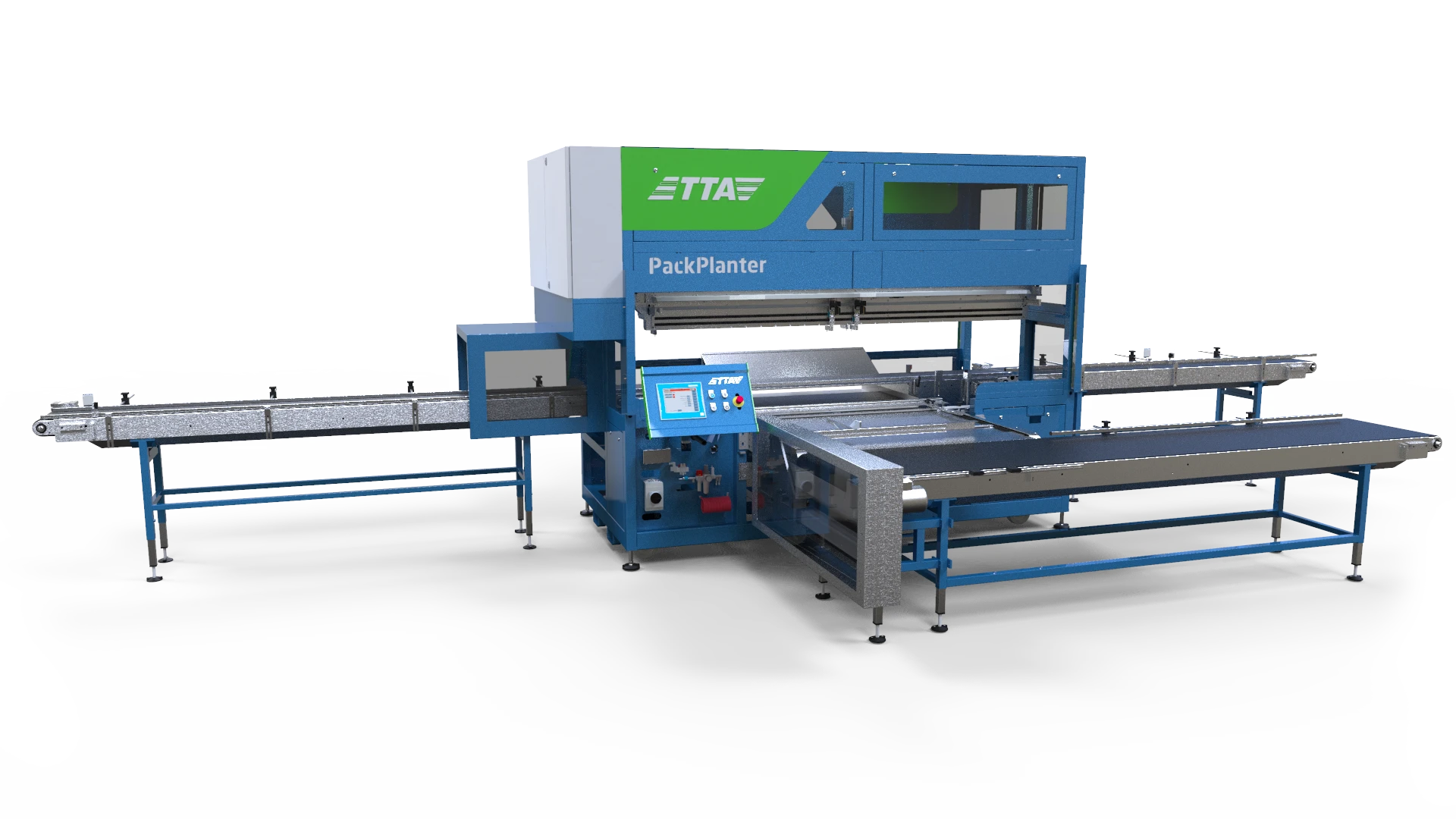

PackPlanter

High-tech transplanter for transplanting into trays, packs, or pots placed in shuttle trays.

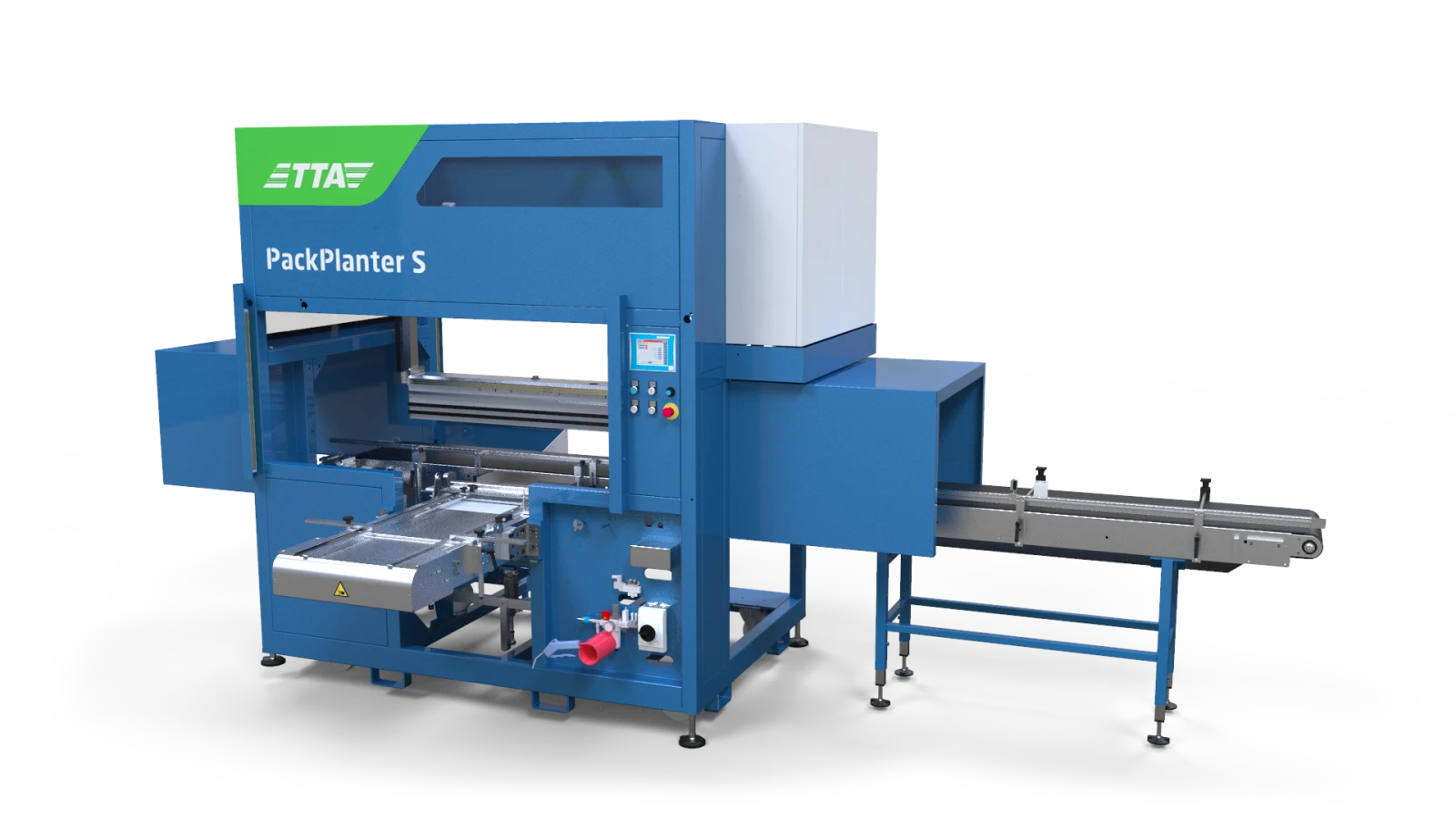

PackPlanter S

Flexible transplanter for all sorts of young plants.

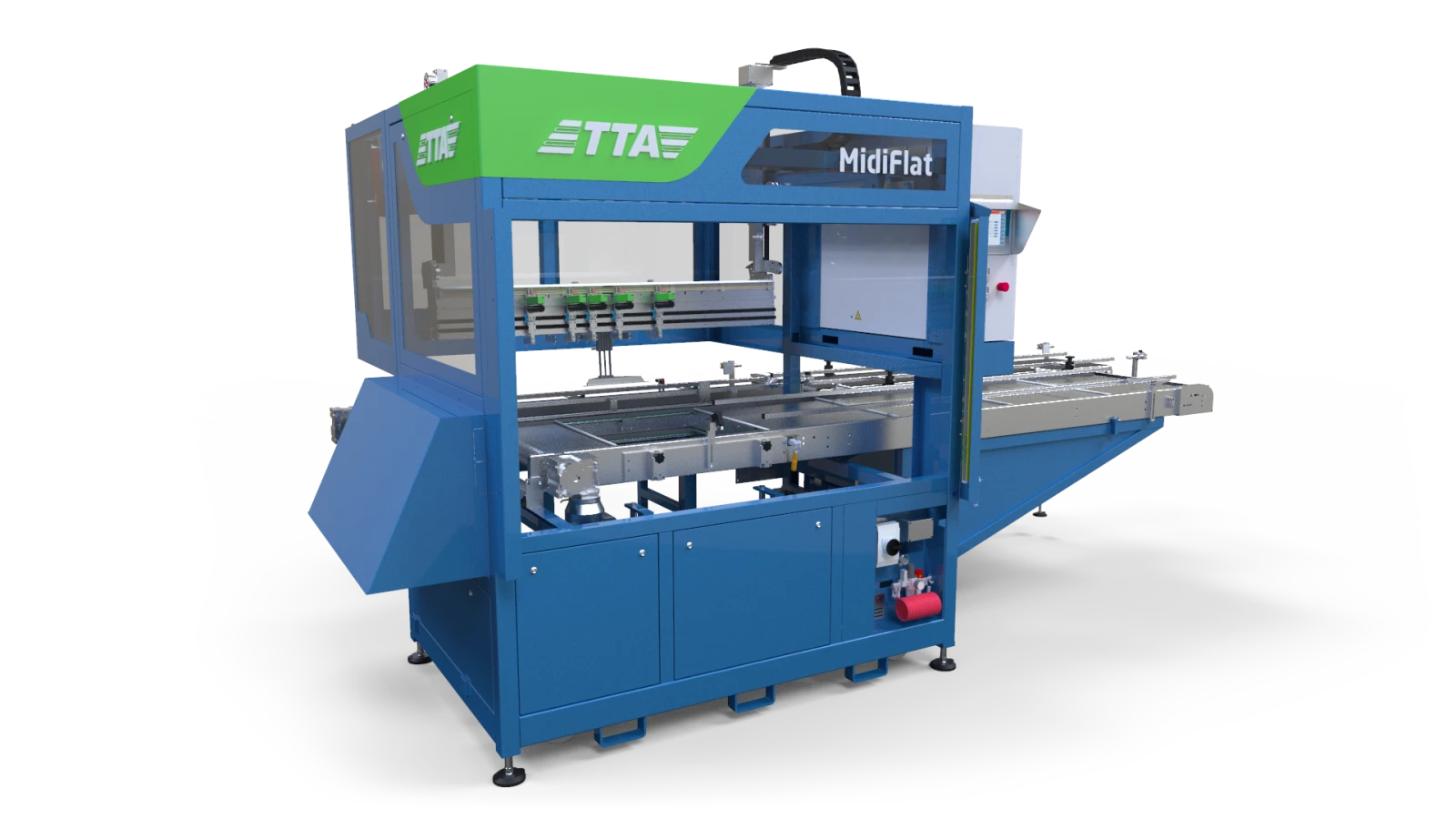

MidiFlat

Transplanter with a capacity of 3,000 to 40,000 plants per hour.

MidiPot

Transplanting over a pot filler with a capacity of 3,000 to 16,000 plants per hour.

MidiCurve

Transplanting over a circular pot filler as well as over a conveyor belt for packs.

MidiVision

Allows for a combination of selection and transplanting.

Transplanting cuttings

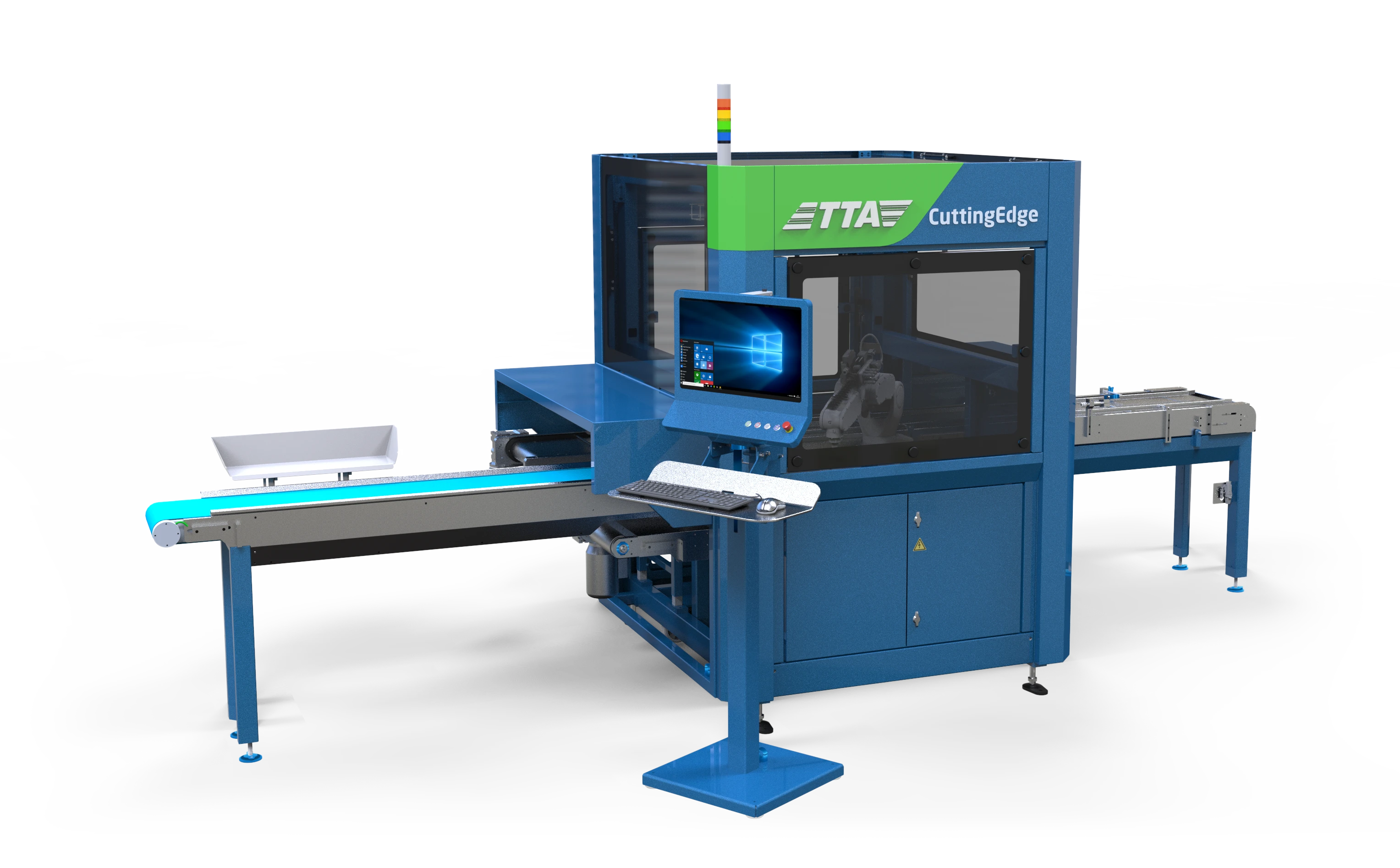

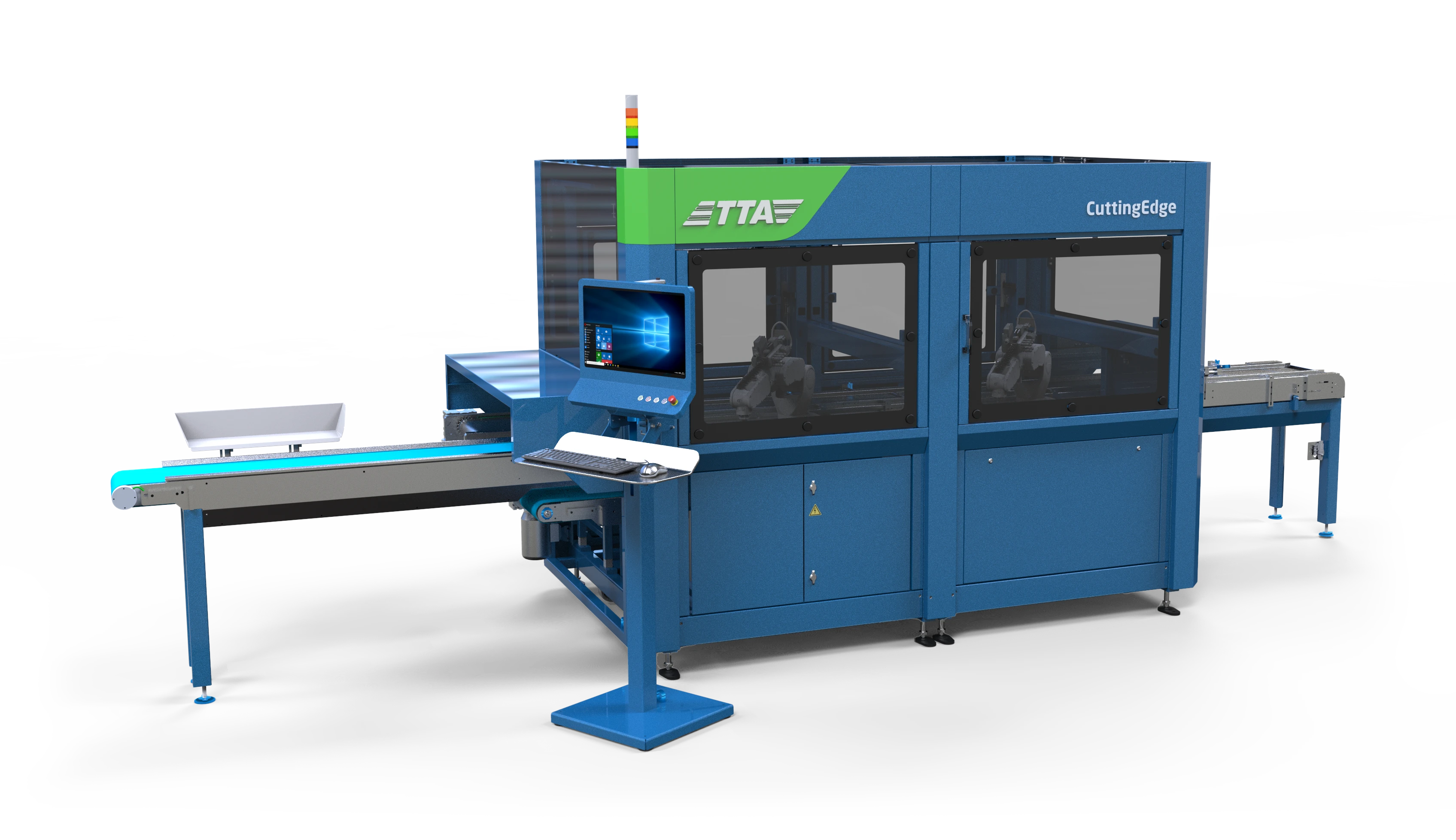

CuttingEdge Single

Single cutting planter with a capacity of 2.000 cuttings per hour.

CuttingEdge Double

Double cutting planter with a capacity of 4.000 - 5.000 cuttings per hour.

CuttingEdge Triple

Triple cutting planter with a capacity of 6.000 - 7.000 cuttings per hour.

Manual Sticking Line

A double conveyor system with stop positions for individual trays and corresponding work positions.

Sorting

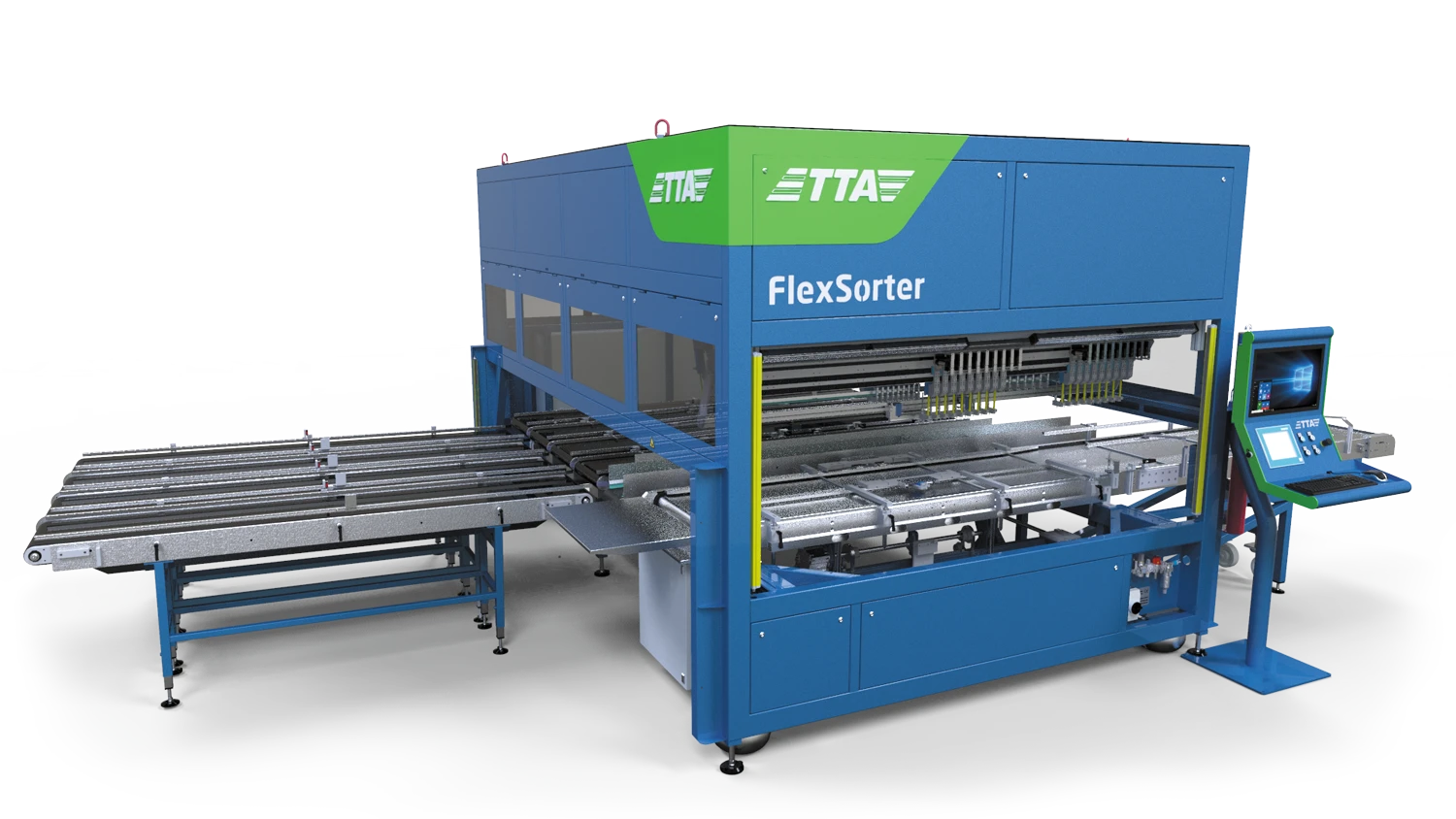

FlexSorter

The FlexSorter combines transplanting and multiple class selection into one simple step.

FlexSorter XF

Ultra high-speed grading line.

MidiVision

A combination of selection and transplanting.

MaxSorter

High-speed grading machine for transplanting into a maximum of four grades.

FlexPlanter

Transplanter that combines transplanting and selecting.

Various

Argos

Innovative solution for scanning and analyzing trolleys.

Drill Unit

Comprehensive solution for drilling & dibbling

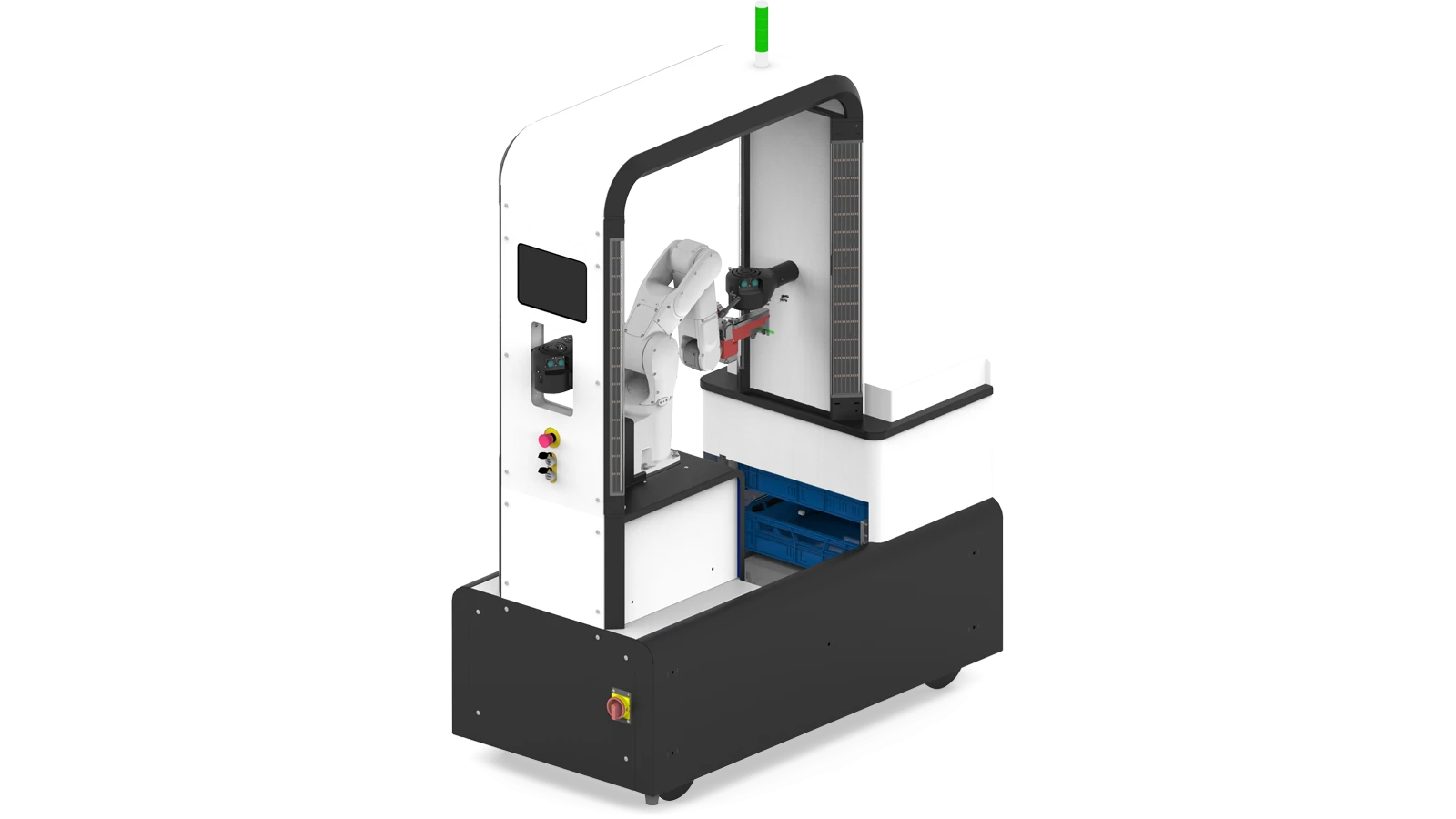

LINR

High-speed linear moving picking & placing robot.

TLF

TLF table and trolley loading system for flats/trays

HS4

Automatic application of handles on bedding plant packs.

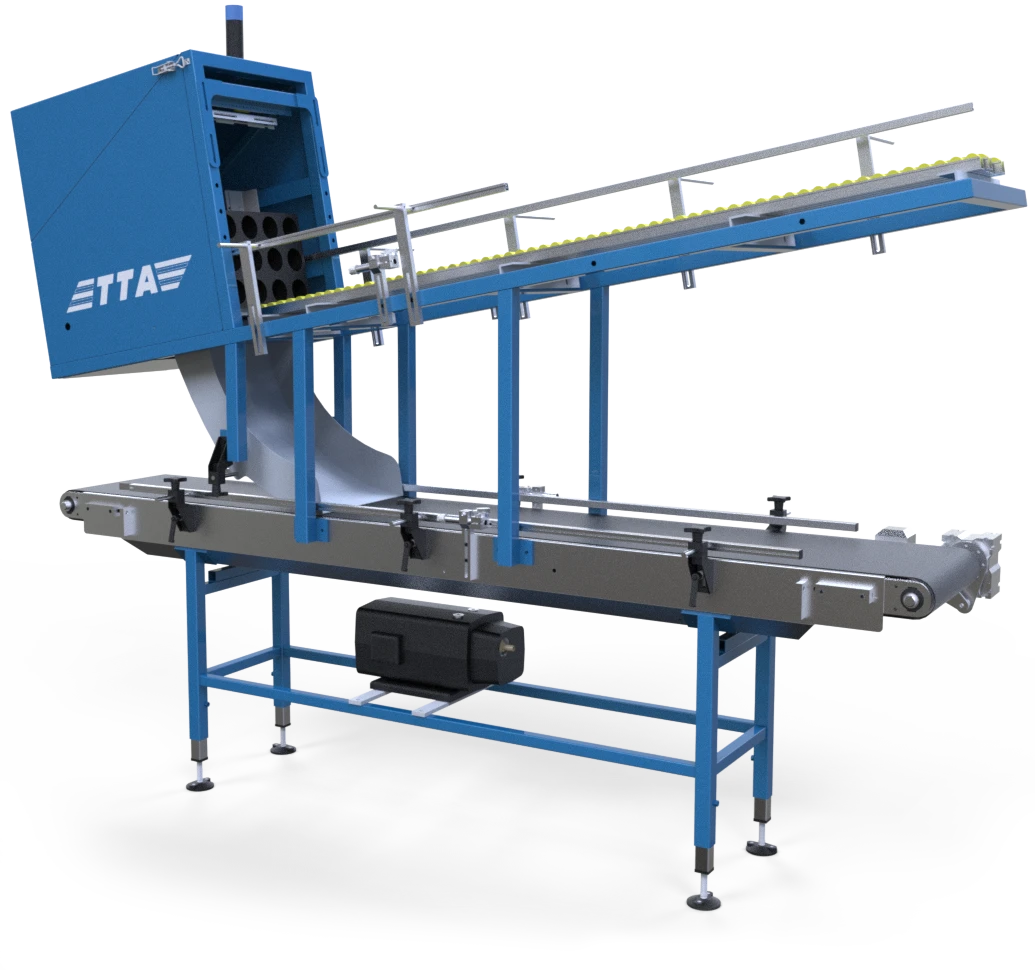

PackDestacker

High-speed destacker for bedding packs.

FlexFiller

High-speed template filler with a minimum of recirculation substrate.

.webp)

PotDestacker

A compact machine designed for swift and precise destacking of pots.

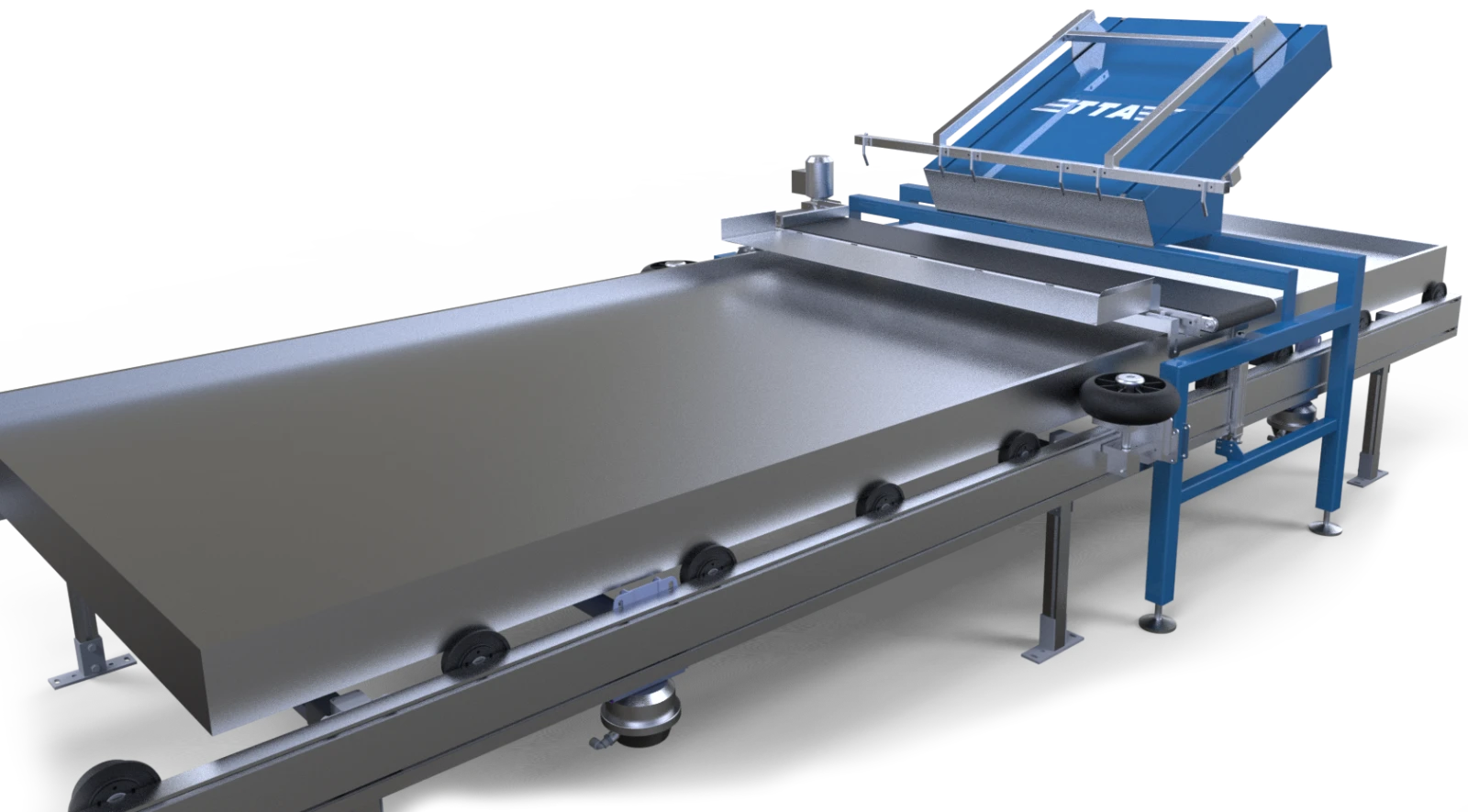

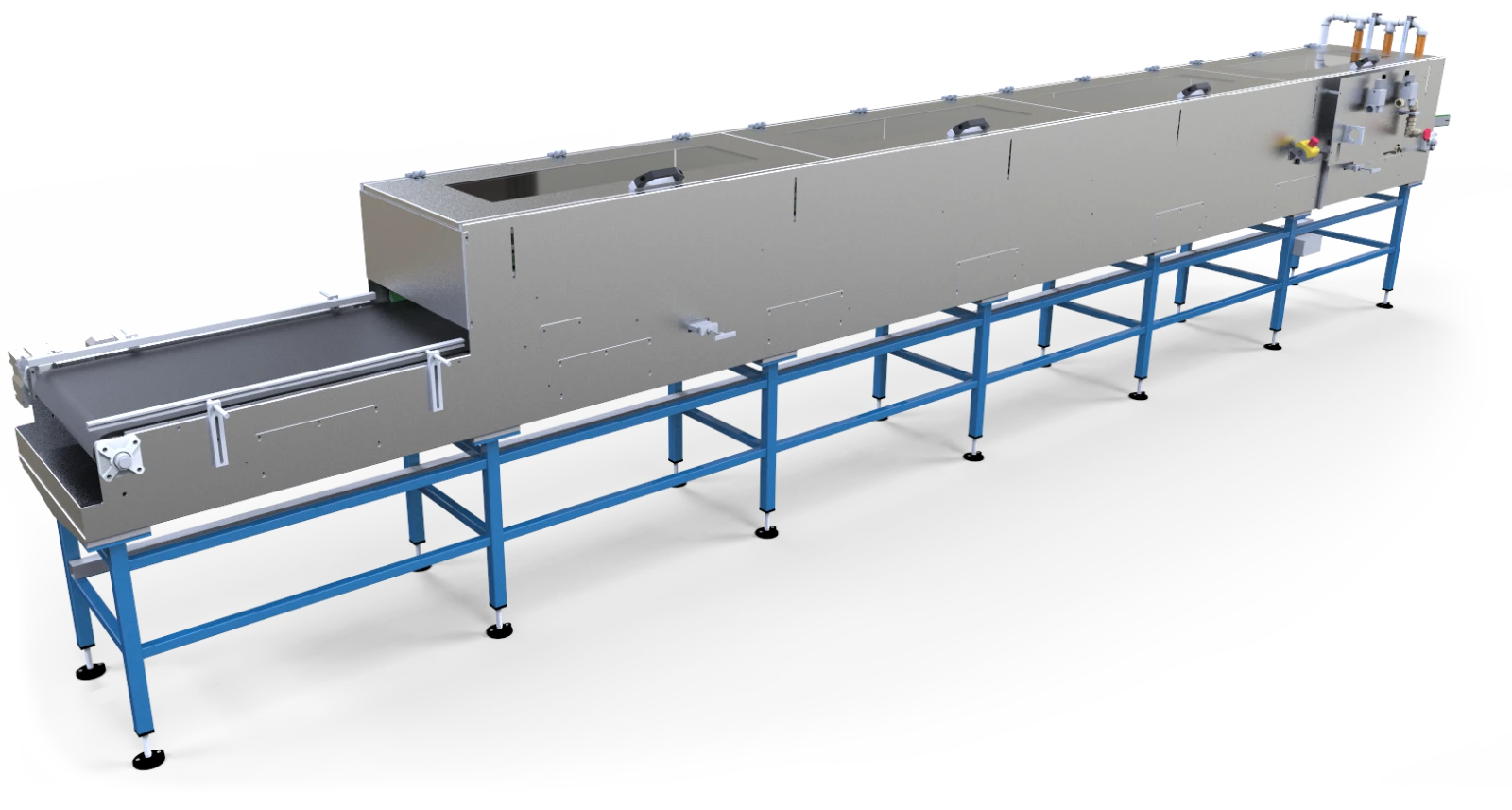

Watering line

A high-quality conveyor system in a stainless-steel drip bin.

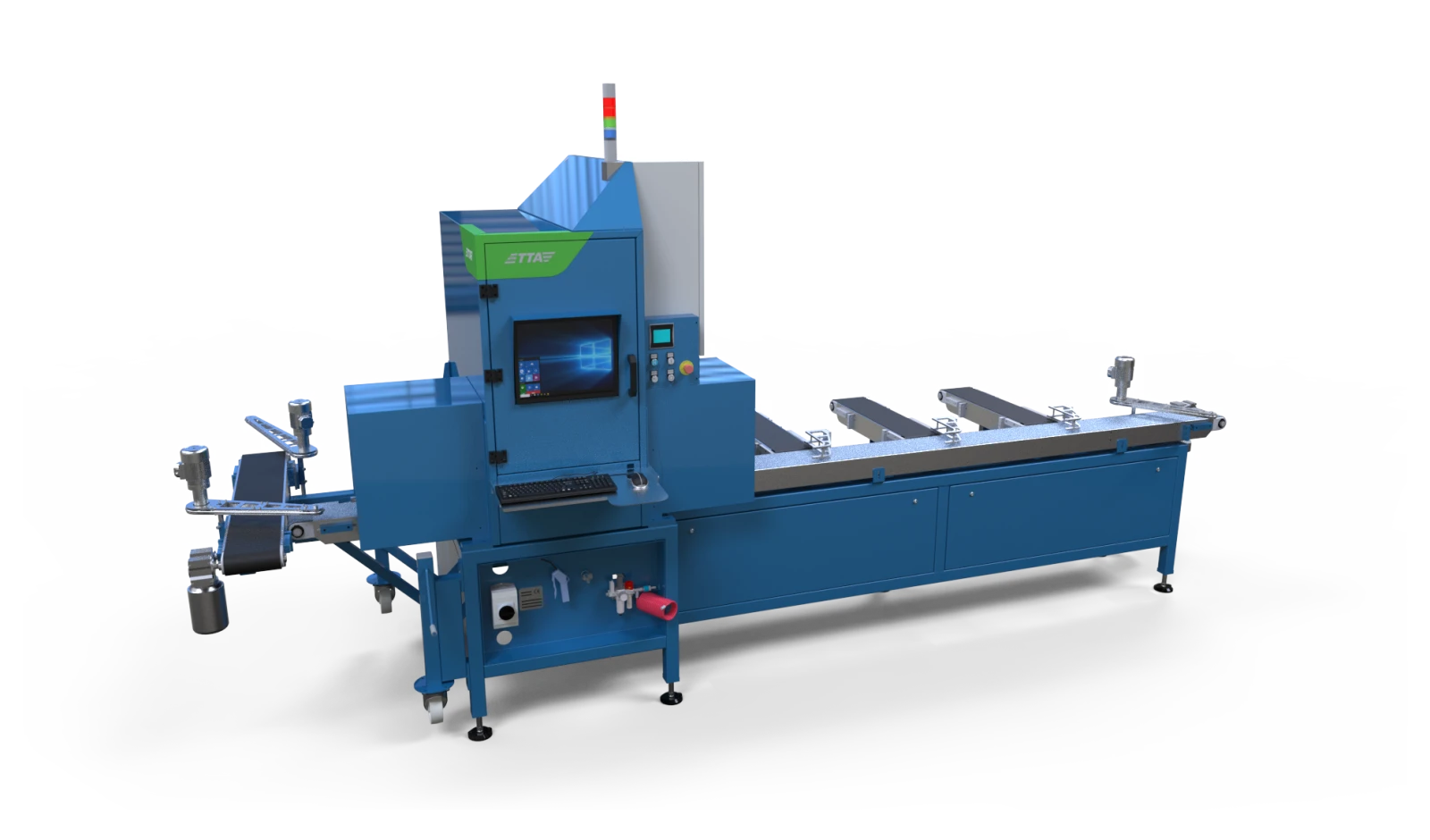

PotSorter

A high-quality fully automatic grading line for pots.

.webp)